Your Bottom Line is Our Business

Mining companies move the world and it takes a lot of fuel to make it happen. The EVO-MT™ System can dramatically improve the profitability of mining operations by replacing diesel fuel with a more sustainable and less expensive alternative. Natural gas is the fastest growing alternative fuel in the world today with 20 million natural gas-powered vehicles expected on the road by 2016. Until now, large mining companies could only stand-by and watch... no longer. The EVO-MT™ System is a game changing technology that allows our customers to stop spectating and start saving.

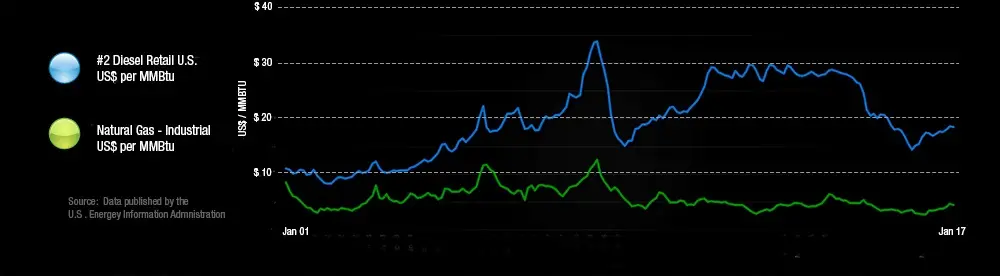

The EVO-MT™System provides savings by allowing mine haul trucks to operate on a mixture of natural gas (LNG) and diesel fuel. The amount of diesel fuel replaced with LNG typically ranges from 50% to 60% over the complete duty-cycle of the haul truck. For example, a haul truck that normally consumes 800 gallons of diesel fuel per day will see this amount decrease to 400 gallons (50% replacement) while operating in LNG+D mode. Since it takes approximately 1.6 gallons of LNG to provide the energy of 1 gallon of diesel fuel, the 400 gallons of diesel are replaced with approximately 640 gallons of LNG. The cost savings can be calculated by taking the 100% diesel mode cost (800 gallons per day x unit cost) and subtracting the LNG+D mode cost (400 gallons diesel per day x unit cost + 640 gallons LNG per day x unit cost). The savings generated are directly related to the cost differential between LNG and diesel fuel on an energy equivalent basis. Using a diesel cost of US$26.00 per MMBtu (US$3.51 per gallon) and an LNG cost of US$12.00 per MMBtu (US$1.00 per gallon), the approximate savings in this example would be $800 per day or close to US$290,000 per year for one truck. Extended to a fleet of 25 trucks, the annual savings using the EVO-MT™System are in excess of US$7MM. In addition to direct fuel cost savings, the 25 truck fleet used in this example would displace over 3.6 million gallons of diesel fuel on an annual basis.

The EVO MT™System provides savings by allowing mine haul trucks to operate on a mixture of natural gas (LNG) and diesel fuel. The amount of diesel fuel replaced with LNG typically ranges from 50% to 60% over the complete duty-cycle of the haul truck. For example, a haul truck that normally consumes 3000 liters of diesel fuel per day will see this amount decrease to 1500 liters (50% replacement) while operating in LNG+D mode. Since it takes approximately 1.6 liters of LNG to provide the energy of 1 liter of diesel fuel, the 1500 liters of diesel are replaced with approximately 2400 liters of LNG. The cost savings can be calculated by taking the 100% diesel mode cost (3000 liters per day x unit cost) and subtracting the LNG+D mode cost (1500 liters diesel per day x unit cost + 2400 liters LNG per day x unit cost). The savings generated are directly related to the cost differential between LNG and diesel fuel on an energy equivalent basis. Using a diesel cost of US$26.00 per GJ (US$.93 per liter) and an LNG cost of US$12.00 per GJ (US$.43 per liter), the approximate savings in this example would be $800 per day or close to US$290,000 per year for one truck. Extended to a fleet of 25 trucks, the annual savings using the EVO MT™System are in excess of US$7MM. In addition to direct fuel cost savings, the 25 truck fleet used in this example would displace over 13.5 million liters of diesel fuel on an annual basis.