-

EVO-MT®

Air/Gas Mixer

» Read More -

EVO-MT®

Knock Module and Sensor

» Read More

-

EVO-MT®

LNG Storage Pod

» Read More -

EVO-MT®

Electronic Control Unit

» Read More

-

EVO-MT®

Diesel Fuel FLow Meter

» Read More -

EVO-MT®

Methane Gas Detector

» Read More -

EVO-MT®

Gas Flow Meter

» Read More -

EVO-MT®

Emergency Stop

» Read More

-

EVO-MT®

Quick Connect Fueler

» Read More

EVO-MT® Electonic Control Unit

The EVO-MT® System includes a powerful Electronic Control Unit (ECU) that monitors critical engine, chassis and system data and uses this information using Dynamic Setpoint Protection® to control the operating fuel mode of the engine. The ECU also provides sophisticated engine protection and monitoring functionality with pre-alarm, alarm and system shutoff logic that allows the engine to be switched from NG+D® mode to diesel-only operation seamlessly and automatically. These protective systems and control algorithms ensure continued engine reliability and uptime when operating on LNG. The ECU monitors critical engine parameters including exhaust gas temperature, manifold air temperature, manifold air pressure, engine knock, engine coolant temperature and engine speed. Each ECU data channel is sampled 50 times per second (50 Hz) ensuring rapid detection and correction of anomalies.

EVO-MT® Flame Detector

The flame detector is mounted in the engine bay and continuously monitors for open flame to provide a LNG shut down signal to the ECU.

EVO-MT®Zero Knock Module and Sensor

The EVO-MT® System incorporates a proprietary Zero Knock System that includes knock sensors mounted on each cylinder and a Zero Knock Module (ZKM). The system “listens” to each cylinder at a precise moment during the combustion event for a discrete frequency that indicates the onset of pre-ignition or detonation. The ZKM continuously communicates with the EVO-MT® ECU to prevent over fueling that could lead to engine damage.

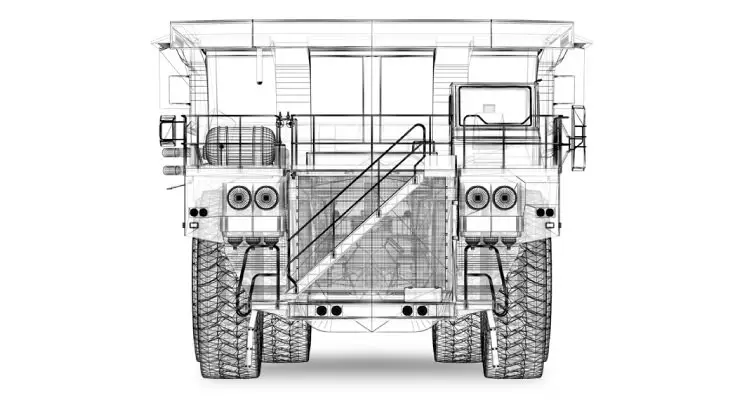

The GFS EVO-MT® System Air/Gas Mixer with Integrated Throttle Body

The EVO-MT® System uses a proprietary air/gas mixing device that has been designed using computational fluid dynamics to ensure optimum blending of the natural gas and engine intake air in order to provide uniform distribution of the gas to the individual cylinders. The low restriction air-gas mixer ensures that adequate air-flow is maintained to the engine and that operating efficiencies are not compromised by installation of the device. The computer aided designed mixer is built to aerospace tolerances using CNC machining processes and is assembled using state of the art welding techniques. Gas flow is controlled by the EVO-MT® System ECU's commands to the integrated throttle bodies mounted to each air/gas mixer. One air/gas mixer is installed just upstream of each turbo compressor inlet. The mixer shown here also incorporates a mass air flow sensor. This version of the mixer is currently used on systems designed for installation on electric drive haul trucks.

EVO-MT® Gas Flow Meter

The gas flow meter is installed in the cab of the truck to enable real time monitoring of the actual LNG fuel flow rate.

EVO-MT® Emergency Stop

Two emergency or E-Stops are installed on the vehicle. One is installed in the operator’s cab within easy reach of the drive and the other on the outside of the truck accessible to ground personnel if immediate manual shut out of the system is required. Also installed on the E-Stop panel are annunciation lights that show the status of the EVO-MT® System.

EVO-MT® Diesel Fuel Flow Meter

The diesel fuel flow gauge is installed in the drivers cab to provide real time monitoring of the diesel fuel flow.

EVO-MT® Methane Gas Detector

TThe gas detector is mounted in the driver’s cab to continually monitor for combustible levels of methane gas to provide an immediate signal for the ECU to shut off the LNG supply to the system.

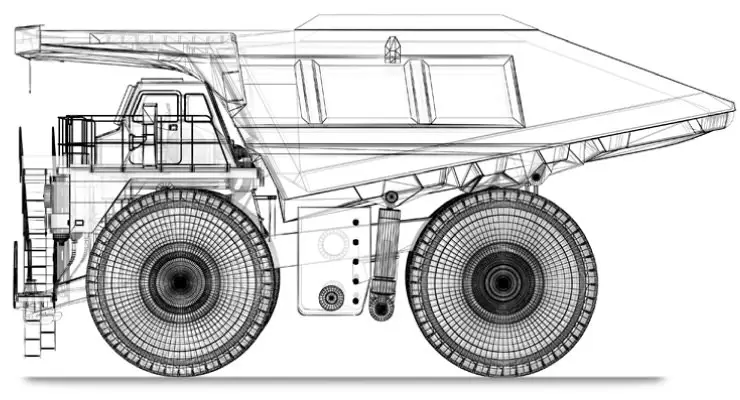

EVO - MT® LNG Storage Pod

The EVO – MT™ Pod safely houses the LNG in cryogenic tanks, evaporators, gas train and regulators, etc. It has been structurally engineered for the harsh environment that mine haul truck must endure. Maintenance staff will like the tilt back feature that keeps the pod out of the way during engine maintenance. Safety was a primary concern in the design. The unique shape allows the driver to exit through the passenger side door should the need arise. The solution shown here is for the Caterpillar 777 series of trucks. Other mechanical drive trucks will have a similar solution. EVO-MT Systems for electric drive trucks are currently under development and will employ a different fuel storage solution.

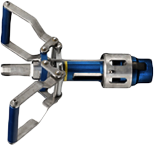

EVO-MT® Quick Connect Fueler

The quick connect LNG Fueling Nozzle delivers for a 50 gallon per minute flow rate to allow for fast refueling. Safety features on the receptacle and nozzle prevent leakage while refueling. Both incorporate independent shut off valves should a forced separation occur. The rugged construction is designed for the harsh environment encounter in the mining sector.