EVO-SP® System Technology Overview

The EVO-SP® System is a retrofit technology that allows stationary diesel engines to operate on a mixture of natural gas and diesel fuel (NG+D®). Installation of the EVO-SP® System requires no major changes or modifications to the converted engine and allows for the safe replacement of 50% to 70% of the engine’s normal diesel fuel requirement with natural gas. After conversion to NG+D® operation, the engine can still be operated on 100% diesel fuel without loss of power or efficiency. The EVO-SP® System has been designed to allow for switching of fuel modes during full or part load conditions without interruption in engine speed, power or stability.

EVO-SP® Designed for Performance

The EVO-SP® System utilizes proprietary gas controls that provide ultra-fast response to engine load changes. Unlike traditional retrofit systems, EVO-SP® has been specifically designed for highly cyclical and dynamic applications such as drilling operations, or variable speed pumping, or compressor applications. The EVO-SP® gas control system combines a powerful electronic control unit (ECU) with a fast reacting, integrated mixer throttle-body (MTB). The ECU monitors mass airflow, RPM, fuel flows and other engine data up to 50 times per second and then commands the MTB throttle position to achieve the highest possible gas substitution rates based on the current load condition. This rapid control loop allows the EVO-SP® System to safely and efficiently maximize fuel cost savings and dramatically extend the runtime of stand-by power systems.

Advanced Engine Monitoring with Dynamic Setpoint Protection™

The EVO-SP® System incorporates a revolutionary engine protection technology. Dynamic Setpoint Protection™ (DSP) is a proprietary system that monitors critical engine parameters such as exhaust temperature and vibration levels across the full engine load range. Each monitored parameter has a discrete, “load-specific” safety setpoint referenced to 100% diesel performance curves. DSP allows for maximum gas substitution rates whether operating at light, medium or heavy engine loadings while ensuring that the engine is always operating within OEM specified limits. In addition, the EVO-SP® System offers remote engine monitoring using a proprietary web-based wireless (cellular or satellite) service that includes SP event alerts as well as periodic reporting and general engine reporting using J-1939 protocols.

Engineered for Safety

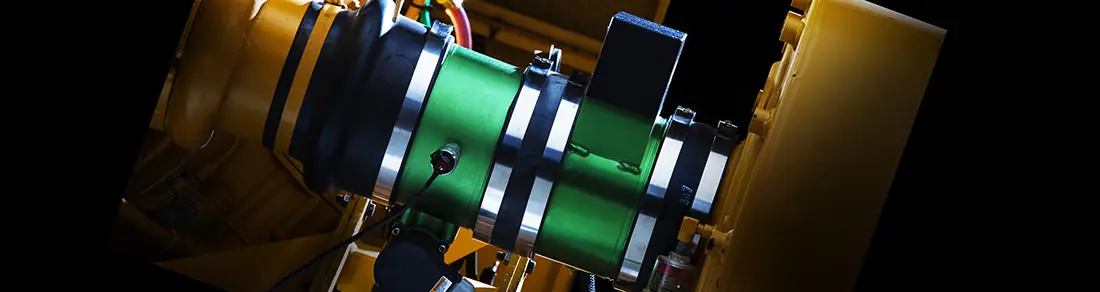

The EVO-SP® System provides a new level of operator safety. Each EVO-SP System comes standard with a remote emergency stop (e-stop) switch, a combustible gas detector and a flame sensor. In the event of an e-stop activation, a gas leak or a fire in the engine room or enclosure, the EVO-SP® System will automatically shut down NG+D® operation, revert the engine to 100% diesel mode and turn-off natural gas supply using a normally closed, dual shutoff solenoid valve. To further enhance safety, each EVO-SP® System is shipped with a fully assembled and tested “gas train” consisting of certified and approved components that meet the most stringent worldwide standards for gas controls.

Advanced User Interface Simplifies Operation

The EVO-SP® System utilizes a state-of-the-art remote touchscreen display that is housed in a NEMA 4x stainless steel enclosure. The touchscreen displays the EVO-SP® Systems proprietary graphical user interface (GUI) that has been designed to convey critical information to the operator in a simple at a glance format. The GUI homepage presents the operator with virtual gauges and bar graphs that are color coded to quickly show normal, pre-alarm and fault conditions. Displayed information includes gas %, throttle-body position, diesel fuel flow, exhaust temperatures, vibration level, gas fuel flow, kWe / HP, manifold air pressure and engine mass airflow. Additional screens can be accessed for fault diagnostics, communications, sensor calibration and System setup.

Which EVO-SP® System is Right for Your Application?

GFS has an EVO-SP® System suitable for most stationary engine applications. See which system is right for you. Download our EVO-SP® System selection questionnaire to find out.