Reduce Operating Costs with EVO NG+D

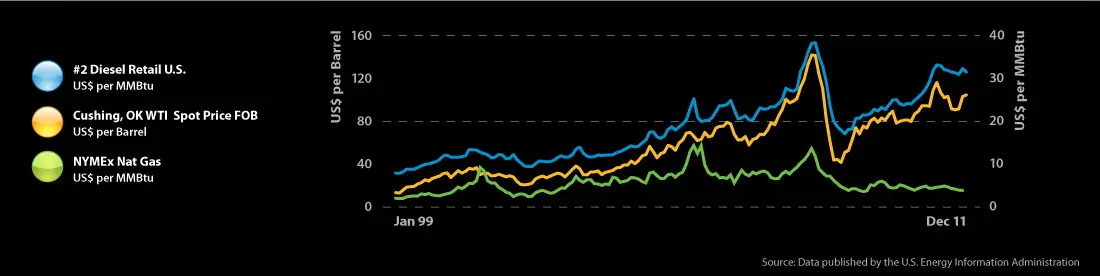

Natural gas has emerged as a leading alternative to petroleum derived fuels. In most markets, the commodity price of natural gas is well below diesel fuel on a cost per energy unit basis. The EVO-SP System has been specifically designed to allow operators of stationary engines to take advantage of this price differential in a safe and efficient manner.

Savings Example: 1000 KW Electric Generator

Operational savings are generated by the EVO-SP System replacing diesel fuel with natural gas on an energy equivalent basis. Using a 1000 KW electric generator as an example, the typical diesel fuel consumption would be approximately 70 gallons per hour or 9.1 MMBtu per hour. Assuming a diesel cost of $3.50 per gallon or $26.9 per MMBtu, the annual diesel cost would be ~$1.96 million based on 8,000 operating hours.

Using the EVO-SP System on this same generator, assuming a 60% displacement of diesel with gas, the diesel fuel consumption would decrease to approximately 28 gallons per hour or 3.64MMBtu. The EVO-SP System would replace 42 gallons of diesel per hour with approximately 5,460 standard cubic feet of natural gas or 5.46MMBtu. Note that the total energy consumption (natural gas + diesel fuel) has remained constant at 9.1MMBtu. Assuming a natural gas cost of $10 per MMBtu, the annual NG+D cost be $1,288,000.

In the above scenario, the EVO-SP System would generate annual savings of $732,000

Use the savings calculator below to estimate gross fuel cost savings on a % basis. For a detailed project pro-forma using the EVO-SP System, please contact lslater@gfs-corp.com

Savings Calculator: English Units Metric Units